ADL expertly cover the manufacturing process responsible for the formation of hollow plastic parts – typically through melting and cooling. Three primary types of blow moulding exist: injection; injection stretch; and extrusion blow moulding.

Read more

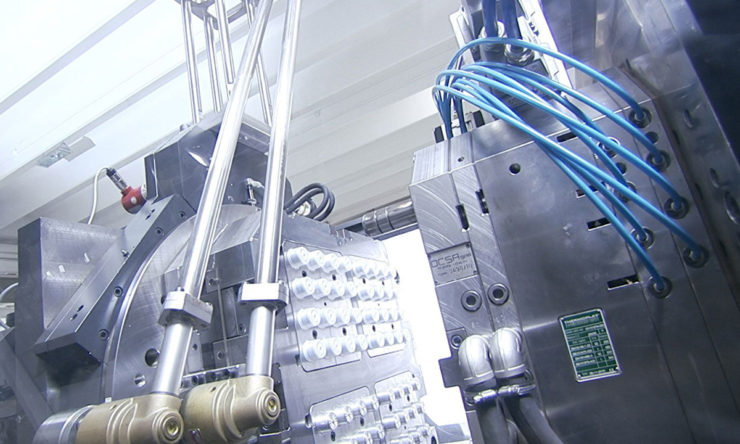

Blow Moulding